Supply Chain Optimization

Visibility and Agility: The missing link in Supply Chain Digitization

Jul 28, 2021

8 mins read

Enterprises have established supply chains with links all over the world, to take advantage of the economies of scale. Cost savings through labor arbitrage has been a key weapon in almost all executives’ armory. However, this advantage is causing all the trouble now.

Since the last two decades, ever since the 3PL revolution and visible successes of globalized supply chains, companies have been trying their best to reduce cost and improve customer satisfaction by making an attempt to build an efficient supply chain. ‘Reduced cost and increased speed’ has become the holy grail of the supply chain for some time now.

The basic fact here is that these two principles contradict each other. There is no cause and effect relationship between cost optimization and increasing speed. Infact, research has shown that they have an inverse relationship – initiatives focused on cost optimization are most likely to reduce service efficiency/speed and vice – versa. To avoid this contradiction, enterprise initiatives mostly depend on the industrial cycle – when demand is high and industry is booming, executives focus on increasing speed and when industry is bearish, the focus is on cost optimization.

However, there is a more fundamental question we must ponder upon — Has reducing cost or increasing efficiency given companies a significant advantage against its competitors?

Hau L. Lee, from Stanford Graduate School, studied the supply chains of around 60 companies with a focus on this problem. He writes that “top-performing supply chains possess three very different qualities. Only supply chains that are agile, adaptable, and aligned provide companies with sustainable competitive advantage”. He illustrates his observations with several interesting examples in his piece. Recent disruptions, such as the one caused by the ripple effects of the Covid-19 pandemic and another by the Suez Canal blockage are live illustrations of this theory.

Adaptability and alignment of stakeholders/partners are wider business problems concerning a business model or process. This piece focuses on the ‘first A’ of a successful supply chain – Agility

Most Enterprises continue to have a single focus on cost optimization and efficiency, and they suffer for not considering agility as a part of the design – when a disruption occurs in any one node of the supply chain. This makes an ‘efficient’ supply chain uncompetitive.

What is Supply Chain Agility?

Simply put, supply chain agility is an organization’s ability to proactively respond to possible volatilities in the market and use the situation to its advantage over competitors. The goal is to achieve a quick response to disruptions as well as to have flexibility embedded in the supply chain. However, in the process of achieving agility, the ultimate goal of the supply chain should not be forgotten – customers should be kept in the center and efficient service to the customer should always be the prime objective.

Executives must answer the below key questions when evaluating their supply chains for agility:

- In case of a demand (for the product/service) and supply (of inputs) imbalance with respect to the current projections, how well can the supply chain manage?

- If there is an internal or an external disruption/disturbance in any one node of the supply chain, what is its effect on the whole network? How fast can the business be restored?

- Do we have the necessary tools and technology to identify and mitigate the supply chain risks proactively? Are we equipped to manage any disruption?

- Do we have a holistic and comprehensive picture of the entire supply chain? Have we identified and mapped the critical dependencies? Is/are the critical node(s) identified?

When we look at the above questions, we realize that agility is a term used in a very broad sense. Like any business unit, supply chain management has three aspects – strategic, tactical, and operational. Similarly, achieving agility in a supply chain also might be split into two broad aspects – strategic agility and operational agility.

Strategic agility deals with proactively identifying and mitigating risks that might impact the long-term business objectives. Almost every company has a common business strategy of reaching more customers and thereby increasing the revenue. Supply chain is a key player in both of these business strategies. Supply chain executives must be proactive in identifying all possible volatility in the supply chain network that might impact the long-term business objectives.

Operational volatility deals with the operational disruptions that might occur in the business environment. While minor disruptions in the environment have always been there, massive disruptions like the recent pandemic tested the supply chains like never before. In a globalized world with cut-throat competition and ever changing customer expectations with respect to service, supply chains cannot afford even minor disruptions in the environment. What gives an enterprise a competitive advantage is an agile supply chain that quickly responds and reacts to the disruption and which can get back to normal operations with minimal impact, whenever there is a change in the environment.

Check Out: Supply Chain Sustainability and Profitability with Green Logistics

How can Supply Chain Agility be Achieved?

Now that we have examined what supply chain agility is, it is time for us to see how this can be achieved. According to a research by Hackett Group in 2019, achieving supply chain agility has always been a top priority of many executives. This was ranked higher in a survey over improving supplier performance, reducing inventory levels, supply chain analytics, etc. However, the same research also indicated that agility is one of the areas that executives had least confidence in achieving. These results indicate the challenges of the mission. But, multiple examples in the industry have shown that agility can be achieved through technology. Successful companies like Unilever, Amazon, IKEA, Walmart have continuously and consistently leveraged multiple innovative supply chain solutions to build an agile supply chain.

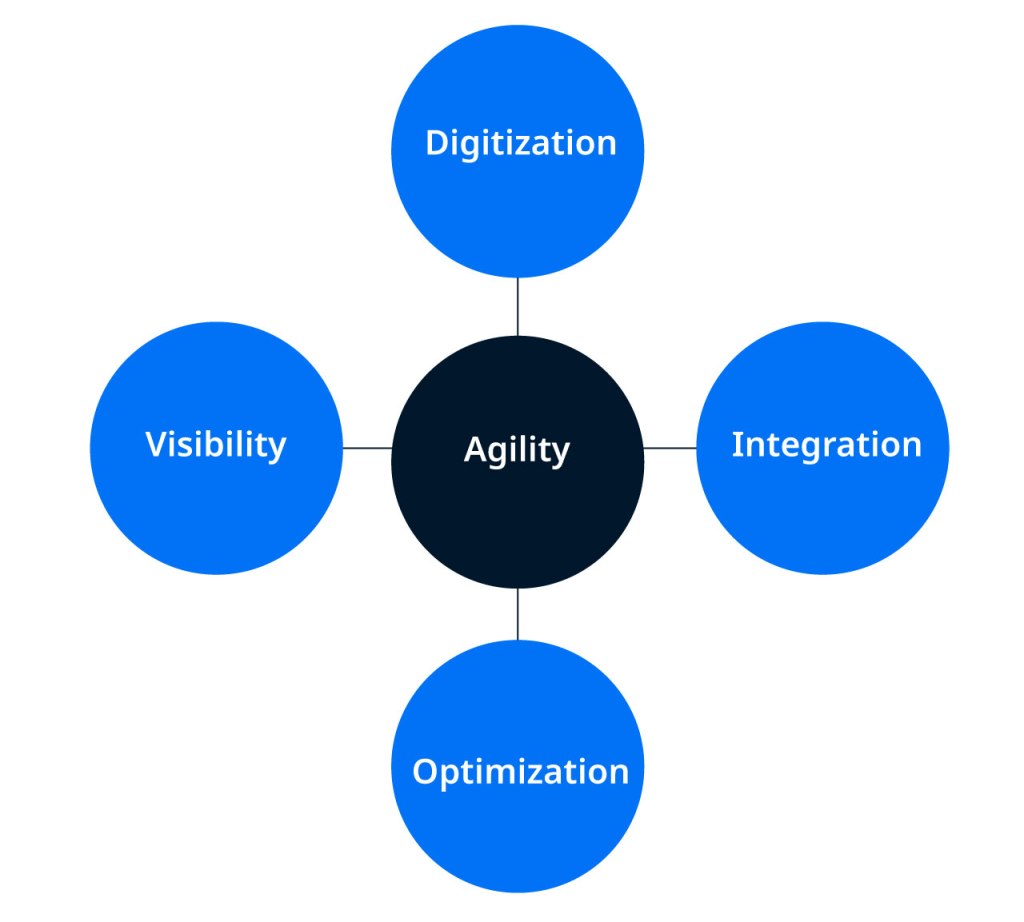

Moving beyond the routinization of the processes and having a more dynamic view of the supply chain is the key to achieve agility. Below is a framework towards building an agile supply chain,

- Digitization: Digitization is the bare minimum to not just achieve supply chain agility, but to also get rid of all the possible inefficiencies in the system. Technology has come a long way and it must be leveraged. If it isn’t, enterprises will not just lose business, but will also waste their existing resources. Enterprise cloud technologies like Locus are the need of the hour for all supply chains.

- Integration – Vertical and Horizontal: We were trained to see supply chain functions like logistics, procurement, etc. as distinct business units – while in reality, these are different wheels of one system. Technical and functional integration among various supply chain functions is the second step towards achieving supply chain agility – as it leads to a holistic view for planning. Data must flow freely in a defined manner among different systems of the supply chain. Integrate all your people, process, and technology (systems)!

- Design and Network Optimization: Strategic supply chain agility is all about a careful and conscious supply chain design with a strong emphasis on risks and business continuity planning. All functions of the supply chain must be seen as one network (which is not possible without integration) and the network must be optimized with a focus on risks.

- Establishing an end-to-end Supply Chain Visibility: Operational supply chain agility is about careful planning and visibility. Having visibility on all your orders, assets, and resources is the first step towards proactively identifying any potential risks. In case of any operational volatility or disruptions, planning to respond requires the executives to know the ‘as-is’ state of the supply chain, which can only be achieved by establishing supply chain visibility. Track your supply chain closely on a dashboard to be agile!

While a focus on cost optimization and efficiency might give short term results on the balance sheet, for a long-term win over competition, focus must be on supply chain agility. Agility initiatives might not be a quick win and might be challenging to implement, but they give a strong advantage to the business in the long run. The world today has a heavy focus on consumerism and convenience – it demands a focus shift on agility at all levels!

References:

- https://hbr.org/2004/10/the-triple-a-supply-chain

- https://www.supplychain247.com/article/no_one_can_say_you_didnt_try_but_sop_you_havent_solved_the_problem/elementum?oly_enc_id=5689B6265756D2Y

- https://planergy.com/blog/supply-chain-agility/

- https://www.sciencedirect.com/science/article/abs/pii/S0925527308003046#!

- https://hbr.org/2019/06/platforms-and-blockchain-will-transform-logistics

- https://www.supplychainquarterly.com/articles/1045-the-five-dimensions-of-supply-chain-agility

- https://hbr.org/2021/03/its-time-to-rethink-your-global-logistics

- https://www.thehackettgroup.com/blog/understanding-the-benefits-of-supply-chain-agility/

Know more about Locus Products & Solutions – Schedule A Demo!

This post was authored by: Gaurav Shetty

Related Tags:

E-Commerce

How Do Micro-Fulfillment Centers Benefit E-commerce Brands?

Since the start of this COVID-19 pandemic, the online shopping demand has skyrocketed. Consumers who hesitated to buy online are now flocking in huge numbers to make e-commerce purchases. Businesses that did not build their e-commerce capabilities paid dearly for it. It is clear that e-commerce brands are taking over brick-and-mortar stores. Traditional distribution centers […]

Read more

E-Commerce

How Delivery Logistics Software Benefits Brands Involved in Alcohol/Beverage E-commerce?

After witnessing a value growth of over 80% in 2019-2020, the US is poised to overtake China to become the largest alcohol ecommerce market in the world by the end of 2021. Between 2019 and 2024, US total alcohol ecommerce value will grow six-fold, from half that of China to nearly double. – IWSR, Drinks […]

Read moreMOST POPULAR

EDITOR’S PICKS

SUBSCRIBE TO OUR NEWSLETTER

Stay up to date with the latest marketing, sales, and service tips and news

Visibility and Agility: The missing link in Supply Chain Digitization